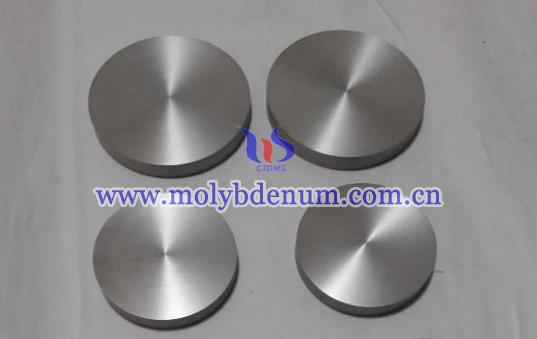

Molybdenum Disc

Molybdenum disc, as one of molybdenum products, is shaped round to fit for parts of machine. Therefore, molybdenum disc shares properties of molybdenum products, which have many special features: excellent electric and thermal conductivity, lower thermal, expansion coefficient, higher bending strength, and so on. Following is a table to show its main features:

| Diameter (D) | 4.5~102(mm) |

| Thickness (H) | 0.25~6.5(mm) |

| Purity | ≥99.95% |

| Thermal expansion coefficient (0~700℃) |

4.7~6.1*10-6/℃) |

| Density | ≥9.90g/(cm3) |

| Bending strength(20℃)) | >420Mpa |

| Resistivity | ≥6.26*10-6.cm(20℃)) |

The surface of molybdenum disc is smooth and cleaned, which is similar to molybdenum sheet, for molybdenum disc can be made from molybdenum sheet.

Molybdenum disc is made to the thyristor parts and its electric parts supporting base material, or be inserts of machines. Meanwhile, it is used as mounting material for power semiconductor devices due to its significantly lower cost and weight. Further applications include the use of molybdenum as heat sink bases in IC’S, LSI’S and hybrid circuits.

Here, the content of molybdenum disc should be considered:

Impurity no more than % |

|||||||||

| Fe | Al | Ni | Si | Mg | Na | Ка | Са | W | О |

| 0.014 | 0,005 | 0,005 | 0,005 | 0,003 | 0,015 | 0,05 | 0,007 | 0,4 | 0,3 |