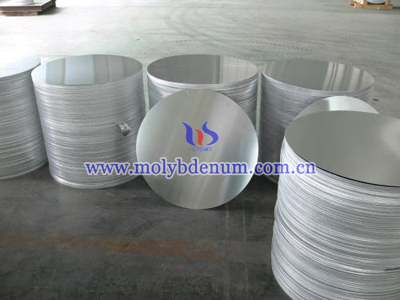

Molybdenum Disc with Rhodium Plated

Molybdenum disc can be plated lots of material, and rhodium is one of the most popular materials. Molybdenum disc with rhodium plated is made of molybdenum with its density of 99.95% from rolled Mo-sheet, and it shall be plated with 0.3-0.4μm rhodium.

Surface condition of molybdenum disc with rhodium plated has no cracks from punching or other operations. Its all edges are absolutely free from burrs. Another surface condition is required—no spots, pip marks and scratches are allowed. Plating rhodium must not show flaws or flake off when testing the adhesion with adhesive tape.

Flatness deviation of molybdenum disc with rhodium plated is ranging from 0.003mm to 0.005mm. The molybdenum disc must be within specification after 12 hours at 300C in vacuum or dry nitrogen.

Molybdenum disc also can be plated other materials, such as nickel or weld performance silver to improve molybdenum slice of the substrate.